Yaxiya Smart Factory

As the global manufacturing industry enters a new era of intelligence and greening, Changshu Yaxiya Weaving Decoration Co., Ltd. actively embraces change, relies on advanced technology and intelligent equipment, and strives to build an intelligent textile factory with international leading level, opening a new chapter of "smart manufacturing".

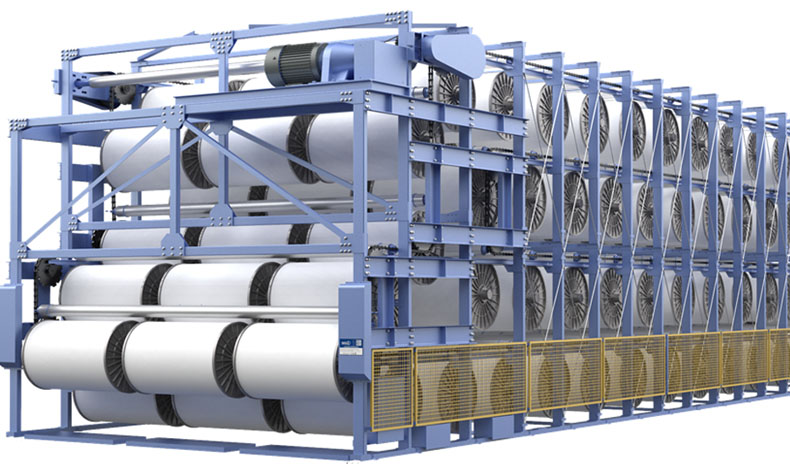

As a comprehensive textile group integrating weaving, printing and dyeing, finishing, finished product manufacturing and R&D, Yaxiya Textile is well aware that intelligence is the key to improving the core competitiveness of enterprises. In recent years, the company has continued to increase its investment in technology, introduced a number of advanced production lines such as imported setting machines, dyeing vats, and washing machines, and realized real-time collection, automatic scheduling and precise control of production data through digital systems, greatly improving production capacity and product consistency.

The factory produces 50,000 tons of finished fabrics annually. Behind this amazing production capacity is the result of efficient collaboration between intelligent equipment and information systems. During the production process, through real-time monitoring of MES (manufacturing execution system), from raw material storage to finished product delivery, each process is traceable, analyzable and optimizable.

Intelligent management system to improve operational efficiency

The Yaxiya Smart Factory has not only achieved automation at the workshop level, but also deployed an ERP system and energy management system at the management level to achieve comprehensive integration and intelligent scheduling of orders, inventory, logistics, energy consumption, etc. Through the continuous operation of the ISO50001 energy management system, the company has effectively reduced unit energy consumption and promoted the implementation of a green production model.

Since the establishment of the company, human-machine collaborative operation has been realized within the factory, and the production line is equipped with intelligent sensing systems and safety interlocking devices, which not only ensures the safety of employees but also improves work efficiency.

01Smart fabric control system

The system uses IoT and AI for real-time monitoring and optimization of fabric production, with functions like order management, scheduling, and quality tracking to boost efficiency and quality.

02Modular fabric control system

Designed for modular fabric production, the system enables precise thermal printing control and supports customization and rapid output through digital decomposition and assembly planning.

03Functional fabric development platform

This smart medical fabric embeds a pressure-sensing chip to monitor heart rate, cardiopulmonary function, and muscle fatigue in real time. Conductive, antibacterial padding keeps the chip close to the body for continuous health tracking.

Advantages

Unique international genes

Since founding, Yaxiya Group has upheld top international standards in operations, governance, and talent development, building a strong global network offering one-stop services.

Diversified customer base

Yaxiya Group serves a diverse, quality customer base with lasting partnerships, offering comprehensive products and earning strong trust.

Leading research capabilities

R&D is key to Yaxiya Group's business, guided by objectivity, independence, and professionalism to deliver timely insights to apparel companies.

Rich project experience

Yaxiya Group launched China’s leading smart production line, earning customer acclaim and becoming a preferred fabric supplier through its expertise and professionalism.

Excellent innovation ability

Yaxiya Group’s culture of sincerity and cooperation fosters creativity. Its skilled, experienced team stays market-savvy to deliver innovative products to customers.

Outstanding professional team

Yaxiya Group has assembled top global talent, building a professional team with strong ethics, innovation, business skills, and proven project execution.